How to Build Assemblies Tips and Tricks

One of the most powerful features in DESTINI Estimator estimating software is assemblies. Assemblies help you create a better, more accurate estimate.

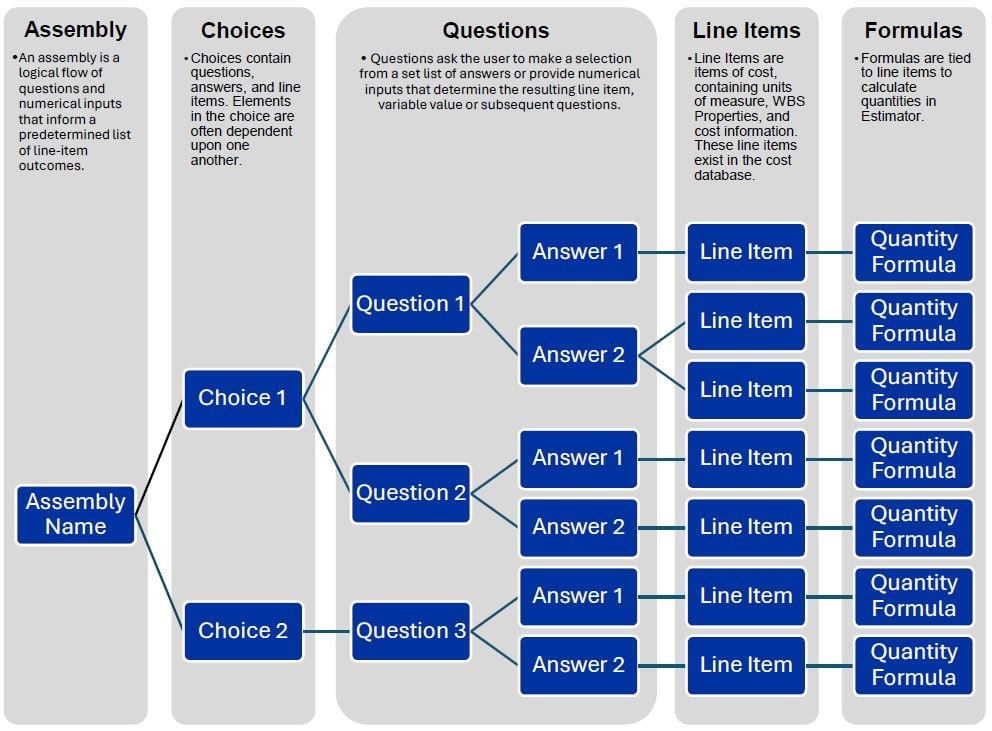

Assemblies are user-defined groups of related cost items in the cost database. Assemblies use questions and variables to apply the right scope items and quantities to the estimate.

These questions are used within choices and variables to request the inputs needed to quantify the line items within the assembly. Assemblies can be as granular or as high level as you need them to be.

Choices

Choices contain questions, answers, and line items. Elements in the choice are often dependent upon one another.

Questions

Questions ask the user to select from a set list of answers or provide numerical inputs that determine the resulting line item, variable value, or subsequent questions.

Line Items

Line items are items of cost, containing units of measure, WBS properties, and cost information. Line items exist in the cost database called DESTINI Data Manager.

Formulas

Formulas are tied to line items to calculate quantities in DESTINI Estimator.

DESTINI Estimator users who leverage assemblies are more precise and more efficient than their line item-only counterparts, as it significantly saves time when creating a new estimate.

If you haven’t started utilizing assemblies yet, we have four tips to get you started.

1. Plan

It’s really important to spend time collecting real world examples of the intended assembly (section details, plan sheets, specs, etc.) so that the finished assembly is applicable to 80% or more of the instances of the scope in the company’s projects.

For example, list all the direct and implied scope for the target assembly in the order needed to construct it. Then review this list with field and precon teammates for completeness and nuance. This is especially important if the scope is not highly familiar to the person building the assembly.

- Group Choices by Like Types that can be reused for other assemblies where appropriate (Masterformat level 1.5 is a good example: 03 10 00 Concrete Formwork and Accessories)

- Create line item detail one layer deeper than your most detailed deliverable.

Example: If you give Trade/Bid Package level summaries as Owner deliverables, but the PM/controller needs Masterformat 2 level detail, line items should be specific to Masterformat 3 level of detail. This enables an explanation of the desired results; a “how did you get here.” - Arrange choices and line items in the order in which the element is constructed. This way, user prompts flow in a natural order and the estimate is propagated such that sorting the estimate by Takeoff Order column reads like a script for the scope.

- Organize assemblies and takeoff prompts with the assumption that your most inexperienced estimator is going to need to find it and use it without assistance.

This will enable faster learning and more efficient onboarding as well as make your database more attainable for your inevitable replacement. - Maximize use of assembly logic and shared variables. If one scope is dependent on another, make sure it feeds off its predecessor.

example: If Excavation Sloping is only necessary when Footing Formwork is “yes” and BottomofFooting-TopofGrade >= 4’, then work that into the assembly logic using Ask When conditions in the assembly logic and IF () statements in formulas. Don’t make users say “yes” when other answers/values they’ve entered will do.

2. Create consistent naming conventions at every level and document them as standards. (Assembly, Choices, Line Items, Formula, Project Properties & Variables).

3. Use standard variables for common takeoff types to optimize Automatic Pricing (Areas instead of Slab Area, Length instead of Footing Length, Perimeter instead of Form Length, etc.)

4. Include the UOM in the formula name (fx_FootingVolumeCUYD) This makes it easier for other teammates to know what the calculation is getting to as written.

If you need help with assemblies, reach out to your customer success representative.

If you are not a DESTINI Estimator user and would like to know more about how assemblies can work for you, click the button below to schedule a demo.

-1.png?width=112&height=112&name=image%20(4)-1.png)